1.Description of Breakfast Corn Flake Processing Line/ Corn Flake Machine:

Cereals Snacks, Corn flakes machines with the feature of Operating easily all-automatic, Self cleaning to save manwork and time, Sanitary food grade, Durable with a long life time.

Corn Snacks Machines is not just a combination of machines, but an integrated process starting with raw material feeding and ending at the packaging room. Thus, the system is quite versatile and able to produce a wide variety of cereal flakes and shaped breakfast cereals.

2. Raw materials: Adopts corn flour as raw materials

3. Products: This line can be used to produce snacks, cereals by adjusting the moulds from extruder

4. Capacity: 150kg/h, 240kg/h, 400kg/h

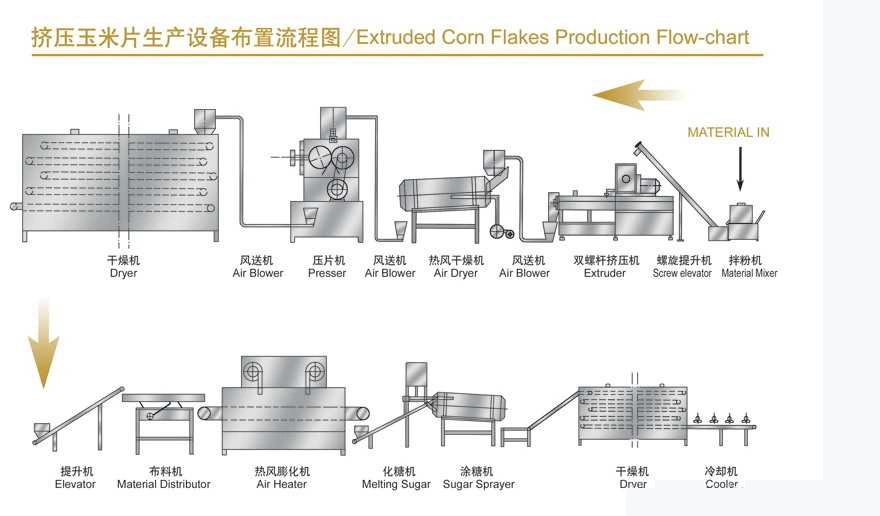

5. Flow chart of Breakfast Corn Flake Processing Line/ Corn Flake Machine:

Mixing system---Extrusion system----Cooling system- Flaking system--Drying system- Toasted system---Sugar Spraying system ---Drying system---- Packing system

6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries.

7. Machines Materials: All the machines are made by stainless steel.

| Model | Installed power | Real power | Output | Dimension |

| MT65 | 70kw | 40kw | 100-150kg/h | 20000x1200x2200mm |

| MT70 | 100kw | 70kw | 200-240kg/h | 25000x1500x2200mm |

| MT85 | 200kw | 150kw | 300-400kg/h | 30000x3500x4300mm |

Formation of Breakfast Corn Flake Processing Line/ Corn Flake Machine:

1 Mixer:There are 3 machine model numbers to choose from base on the production capacity.

2 Conveyor:To convey raw materials to the extruder machine

3 Extruder machine: To choose DSE model extruders base on the production capacity requirement from 100kg per hour to 500kg/h per hour. The raw material include corn powder, cereal powder and so on. Shape of the pellet depends on the moulds.

4 Hoister: Convey cheetos to the dryer, the height of the hoister depends on the dryer.

5 Multilayer dryer:Electric dryer, controlled by control box, temperature range 0-200ºC.Inside is stainless steel double layer mesh net. Drying time is adjustable according to speed. We have dryers of 3 layer 5 meter, 5 layer 5 meter, 5 layer 7 meter, 5 layer 8 meter, 7 layer 8 meter, and 5 layer 11 meter steam dryer.

6 Sifter:To remove scrap

7 Flavoring line: To spray oil and phagostimulant, the equipment are: single roller, double roller, round roller,Varies depends on the different production line setting, to spray oil to the surface of the product and make it even.

8 Cooling conveyor: To lower the product temperature in order to pack it easily.

9 Sifter: To remove the wasted material and ensure quality, meanwhile to ensure the reuse of materials.

10 Packing machine: Manual or automatic packing machine.

Product details:

Our company:

Our clients:

Paking & Delivery:

Our Certification:

Our service:

1. Pre-sale services:

Act as a good adviser and assistant of clients, enable them to get rich and generous returns on their investments.

1.. Select equipment model;

2.. Design and manufacture products according to clients' special requirement;

3.. Train technical personnel for clients.

2. Services during the sale:

Respect clients, devote ourselves to improving the total value of clients.

1.. Pre-check and accept products ahead of delivery;

2.. Help clients to draft solving plans.

3. After-sale services:

Provide considerate services to minimize clients' worries.

1.. Assist clients to prepare for the first construction scheme;

2.. Install and debug the equipment;

3.. Train the first-line operators;

4.. Examine the equipment;

5.. Take initiative to eliminate the troubles rapidly;

6.. Provide perfect service;

7.. Provide technical exchanging.